Installations

2,200 m² dedicated to surface protection and finishing on all type of substrates

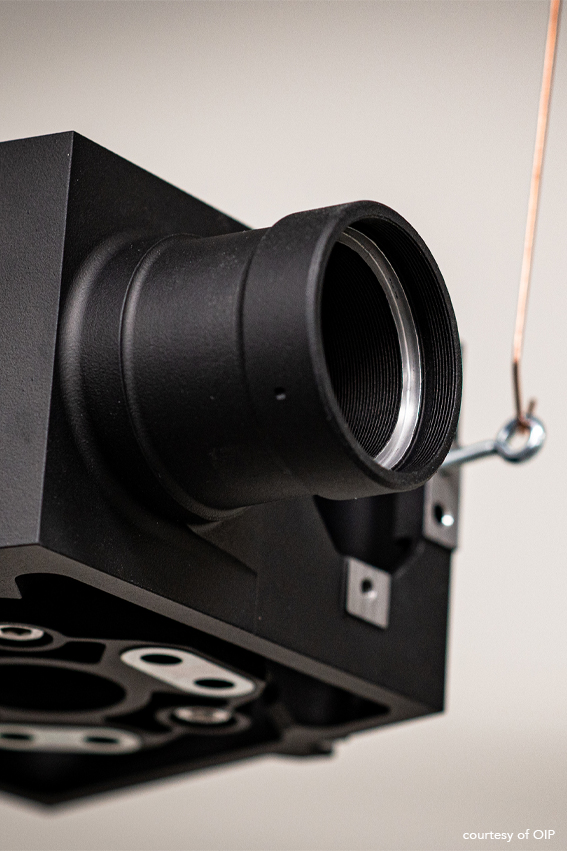

Precision painting

We specialise in precision painting for sectors with exacting traceability requirements. Our equipment enables us to measure all the critical aspects of your specifications.

We mainly work on steel and aluminium alloys, but we can also treat composites, special alloys or plastics.

Are you looking for an applicator who can advise you on technical characteristics, such as CARC, QPL, outgassing properties, electrical or thermal insulation and more? We are the partner you need.

Anti-Corrosion

We are equipped for anti-corrosion treatment, in accordance with the standards in effect (C3, C4, C5).

Do you produce equipment to be used off-shore or in other particularly aggressive environments? We can help you extend the life cycle of your products

Industrial painting

We perform all the painting work for various industries. We can paint any substrate, such as ferrous and non-ferrous metals, plastics and PVC, varieties of wood and wood fibreboard, resins, ceramics, glasses, etc.

Do you want to improve your image by adding a perfect finish to your product? Please feel free to contact us.

Furniture lacquering

We also perform lacquering work on wood for your stylish interiors. Choose between a matte, satin, gloss or ‘Piano’ repolished gloss finish. In addition to lacquering on MDF, we paint and varnish all the kinds of wood in your interior and exterior (doors, window frames, sectional doors, plinths, furniture, etc.).

We can bring your kitchen or bathroom back to life by repainting any panels that can be dismantled.

Détails installations

Our equipment is at the cutting edge of technology, calibrated at regular intervals and maintained in accordance with industry standards.

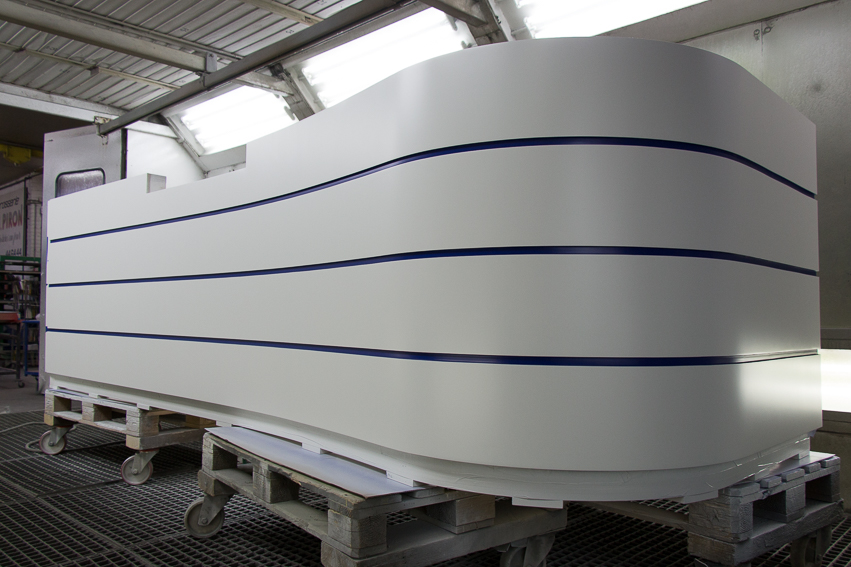

Our 2,200 m2 liquid-paint workshop comprises:

- a clean loading and unloading area with lorry and van access

- a 256 m² thermo-regulated and hygro-regulated state-of-the-art painting cabin for aeronautical parts

- a 80 m² thermo-regulated painting cabin for all your parts up to 4000 x 3000 mm and 3T

- a painting workshop with a controlled atmospheric environment

- different degreasing and preparation areas

- a sanding cabin for small parts

- expertise in the choice of suitable pre-treatment (chemical conversion, anodising, phosphating, electro-galvanising, etc.)

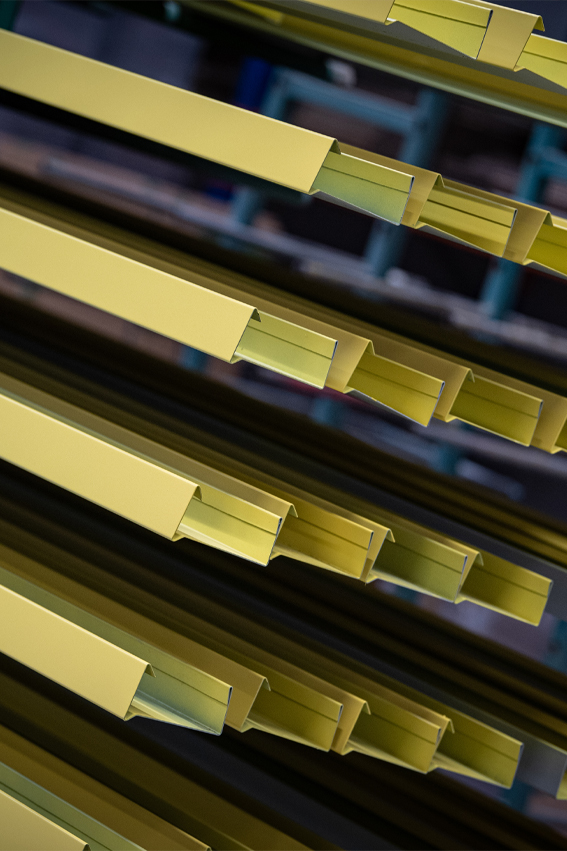

Our 250 m2 electrostatic-powdering space comprises:

- various pre-treatment and degreasing baths

- a rail system

- a ventilated powdering space

- a high-temperature furnace for powder firing (max 250°C) for 3,000 x 3,000 x 1,250 mm parts

- expertise in the choice of suitable pre-treatment (chemical conversion, anodising, phosphating, electro-galvanising, etc.)